Replaceable sensors thanks to the cartridge system

Our gas analyzers make it easy to exchange the gas sensors using a practical cartridge system. Whatever your next project is, simply fit the cartridges and get started. Benefit from minimal downtime and avoid having to send in for annual maintenance. The display gives you a direct overview of all values and the sensor is easy to operate via the menu.

Versatility of a single device

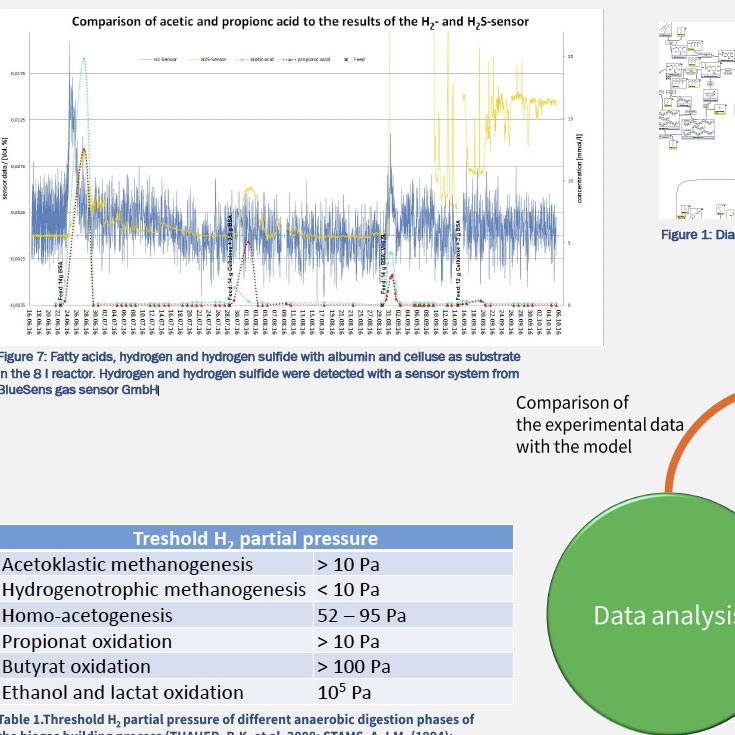

Different applications can be covered with just one device. Whether for aerobic fermentation, e.g. for the production of alternative proteins for the food industry or in the fields of industrial biotechnology, pharmaceuticals or even a biogas application – our gas analyzers always offer the necessary flexibility.

BlueVary consists of a basis station with three plug-in positions for gas sensor cartridges. Two different gases can be measured at once. The third plug-in position holds a pressure or pressure/humidity sensor cartridge. Gas sensor cartridges are selectable according to your application and can be changed easily as required.

BlueVary increases your efficiency

- one device to cover different measurement tasks ➔ choose a suitable gas sensor cartridge for your application

- maintenance free ➔ no need for offsite annual maintenance - minimizes your downtime

- auto compensated pressure and/or humidity ➔ no gas cooler, pumps, valves or other gas pretreatment needed

- connectable to any hose/tube or pipe ➔ use it on your fermenter of choice

- integrated status display ➔ see all sensor information and measurement data at a glance

Simplify process optimization

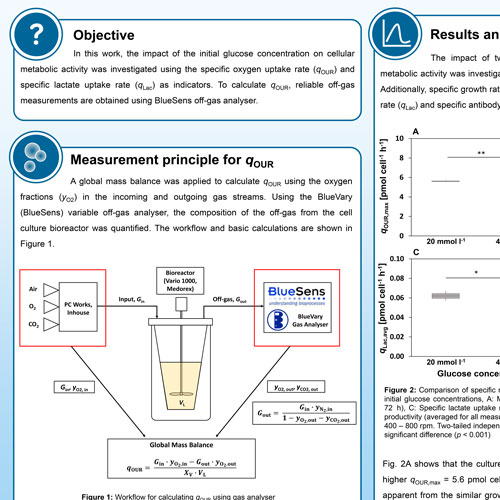

- continuous online fermentation monitoring for cell culture, microbial, algae, fungi or biogas processes

- identify metabolic phenomena and obtain vital process parameters

- applicable from lab to industrial scale

Pichia, E.coli, Trichoderma - Do you work with different organisms, clients and projects? Then the BlueVary with its unique cartridge principle is just right for you. You decide which gas and which concentration range you want to measure. Cartridges can be reordered individually. No need to send in for annual maintenance.

BlueVary Certified Partners

All our distributors are certified partners for our BlueVary. We take great care to ensure that all partners who sell our products are trained directly by BlueSens and are always up-to-date.

Product-Video

Comparison BlueInOne vs. BlueVary

| BlueInOne | BlueVary | |

| housing | stainless steel | Polycarbonate |

| annual maintenance needed | yes | no |

| gases to be measured | combination O2, CO2 | various combinations O2, CO2, H2, CH4 |

| different combinations possible for flexible usage | no | yes |

| integrated display to see measurement and sensor data at a glance | no | yes |

| various connections to connect to every fermenter | yes | yes |

| application in projects with different measurement ranges | calibration has to be changed (if possible) | choose another cartridge |

| one-point calibration to ensure higher accuracy | yes | yes |

| possible to combine with BlueVis software for higher automation grade | yes | yes |

| suitable for biogas applications | no | yes |

Protect your sensor during steam sterilization

The SGP-1 sample gas pump from BlueSens is installed between the pipe and your analyzer. During the sterilization process, it cools down the gas, collects the water and thus protects your sensor from damage.

The analyzer can remain mounted during the entire process.

Sounds good?

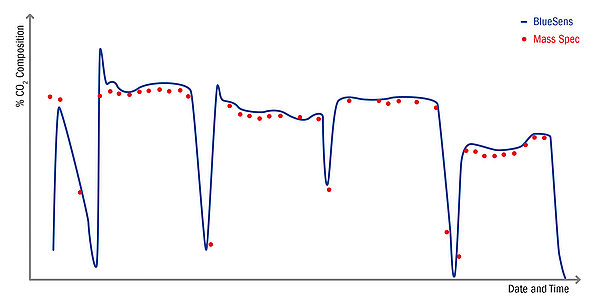

Benefit from continuous off-gas data

See what´s happening when it´s happening. MS and off-gas analyzers - it doesn't have to be either or but can also be complementary. Read here why and how to benefit from continuous off gas measurement made by BlueSens although you already might have a mass spec.