Customer Reviews

We are the experts when it comes to gas measurement technology for bioprocesses. BlueSens stands for longevity, robustness and high quality. BlueSens gas sensors have been proven in processes in the areas of food, feed, pharmaceuticals, biogas (renewable energies), novel food and many more. Our sensors are used in processes with a wide variety of microorganisms, cell cultures, fungi or even in some chemical processes. No matter which area you come from and what you are working on your satisfaction is our top priority. We are therefore pleased to present some selected testimonials here.

Paul J Jansen, Research Scientist, Worthington Biochemical Corp

I have been using the BlueVary off gas analyzer since 2021.

The BlueVary off gas analyzer is a must-have for anyone who wants to improve process optimization. It is easy to use and provides real-time data that can be used to identify and troubleshoot problems. It is easily connected to different systems for recording data, ours is connected to our Eppendorf Bioflo 610 and to a BioFlo120 fermenter. The unit is easily swapped between the two as needed.

One of the big benefits of the BlueVary is the real-time data gives us the ability to quickly detect potential fermentation issues.

The monitor also provides valuable insights into the overall health of the fermentation process. By tracking the carbon dioxide and oxygen levels, I can assess the metabolic activity of my fermentation and ensure that it is proceeding as expected. This information helps me make informed decisions about adjusting fermentation parameters, such as temperature and nutrient supplementation.

The BlueVary is easy to use, easy to set up and gives valuable information during a fermentation. I highly recommend it for anyone who regularly performs fermentations.

Ian Maynard, Manufacturing Technology Director, Enough Foods

Modern process analytics have evolved into sophisticated, reliable methods for evaluating the environment within industrialised fermentation systems. However, for characterising the physiological state of the microorganism to inform process management, the standard, non-invasive approach remains the accurate measurement of the oxygen consumption and carbon evolution rates using instrumentation such as the BlueSens BlueInOne system.

Dr. Ulf Menyes, CEO, Enzymicals

The technical support of BlueSens is very flexible regarding customer needs and takes the whole process into account.

Dr. Alberto Marin-Sanguino, TU München

We had a very tight time schedule for our experiments. BlueSens helped us fast to solve our very demanding measuring task.

Dr. Xavier Garcia Ortega, UAB Barcelona

Thanks to BlueSens devices, the exhaust gas analysis is providing us a lot of new information to improve our bioprocesses.

Marc Hoffarth, Research Associate, University of Applied Science OWL

We use BlueSens‘ sensors and software to develop new technologies. The flexible and reliable systems are a major part of our daily research work.

Prof. Victoria E. Santos, Universidad Complutense Madrid

The use of off-gas analyzers allows us to carry out the development of bioprocesses and their modelling with greater accuracy.

Christian Kreft, EW Biotech

During fermentation, the measurement of oxygen and carbon dioxide in the exhaust gas flow provides a quick indication of how the process is progressing. Within a very short time, you can see whether the microorganisms are behaving as expected or whether there is a deficiency in their supply.

Jonas Koch, Eleva Biologics (Greenovation)

The reliable sensors from BlueSens are very helpful to improve our process understanding.

Kenta Nomura, Marubishi Bioengineering Co., LTD.

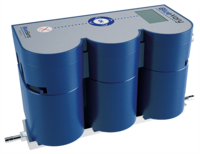

We think that the success of BlueVary lies in the fact that the customers obtain a cost effective, maintenance free device with which they can cover different gas measuring. Especially for oversea countries like us, the cartridge exchange method can minimize the device’s down time so the customers are very relieved. Also, this device can deliver continuous data so it helps our customers to optimize their processes.I think it’s an very attractive product.

Benoit Gros-Louis, LALLEMAND BAKING NA

We are very pleased with the YeastForce device. It is easy to use and calibrate. We like that the system can provide the dough volume and gas retention capability in addition to the total gas produced by the yeast in one measurement. The software is well designed and easy to use for the laboratory technicians. We can easily set-up tests templates that prevent errors. The YeastForce also demonstrated the lowest variability among all the gas measuring devices assessed. The fact that we can run a simple 1-point calibration with a volume inspection is a key point for us by making sure the precision of the results is optimal. Finally, BlueSens support was very good during our implementation.

Marcus Ehrhardt, LALLEMAND BAKING NA

We are very satisfied with the measuring device. Above all, we like the large number of useful measurable parameters such as dough volumes and gas retention capacity very much.

In addition, these are displayed very well and clearly, also graphically. The measurement methodology is sound, and suggestions for improvement and optimization that we suggest are implemented. What we would like to emphasize in particular is the very uncomplicated, direct and fast way in which they respond to our special requirements and wishes and implement them.

Anna Krottenthaler, LALLEMAND WIENINGER

We are very satisfied with the new measuring device. We get comparable values compared to our old device and it is much easier to use.