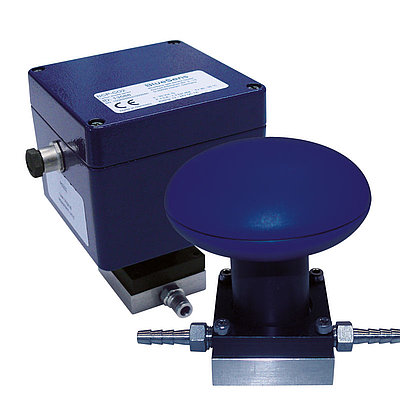

Technical Short Facts

- Measuring principle: infrared, dual wavelength

- Measuring range 0…100 Vol.% CH4

- Drift < ± 2% reading / year

- Accuracy <0,2% FS (full scale) ± 3% value

- Housing Aluminium (IP65), PA

- Mechanical connections G 1¼”, GL 45, Tri-Clamp SMS38, hose connection 4-12 mm etc.

- Output RS232, 4-20mA, Ethernet, USB

- Pressure range: 0.8 - 1.3 bar absolute pressure; 11.6 – 18.85 psi absolute pressure

- other pressure ranges on request

- Pressure dependence: compensated

- CE: EN61326-1:1997 +A2:1998

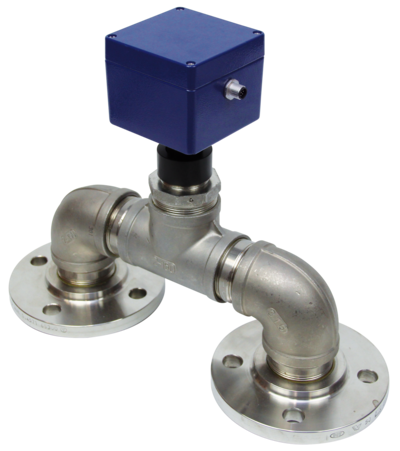

BCP-CH4 analyzers are suitable for measuring methane in biogas applications or process development with methanogenic or methanotrophic organisms. BCP-CH4 gas sensors can be used in any scale of biogas process from lab to industrial scale digesters and all scales of industrial microbiology processes from lab to manufacturing scale. Data transfer to process control systems is simple. BCP-CH4 can be used directly on the gas stream with no requirements for pretreatments. All BCP-analyzers are available with aluminium (pilot to industrial scale use) or PA (lab scale) casings. BlueSens offers the Yieldmaster series for customers interested in BMP (bio methane potential) determinations.

BCP-CH4 – optimize your output

- Reasonably priced in-situ gas analysis ➔ non-invasive measurement

- No minimum gas flow needed

- Direct integration in gas pipes, installation of additional gas pipes is not necessary

- No extra gas cooler, no pumps

- Fast installation due to standard connection

- Low maintenance costs

- Factory calibration using certificated test gases

Application areas

- biogas production plants

- chemical industry

- digestion reactions

- methanogenic or methanotrophic organisms

Protect your sensor during steam sterilization

The SGP-1 sample gas pump from BlueSens is installed between the pipe and your analyzer. During the sterilization process, it cools down the gas, collects the water and thus protects your sensor from damage.

The analyzer can remain mounted during the entire process.

Sounds good?

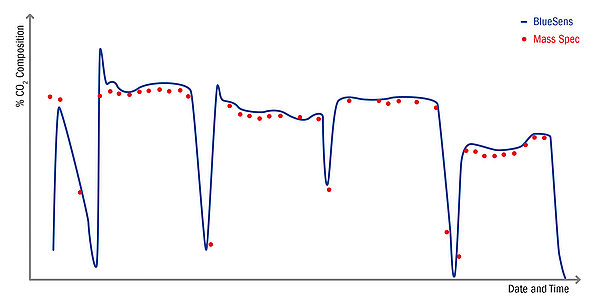

Benefit from continuous off-gas data

See what´s happening when it´s happening. MS and off-gas analyzers - it doesn't have to be either or but can also be complementary. Read here why and how to benefit from continuous off gas measurement made by BlueSens although you already might have a mass spec.