Stop missing essential details! We deliver continous data

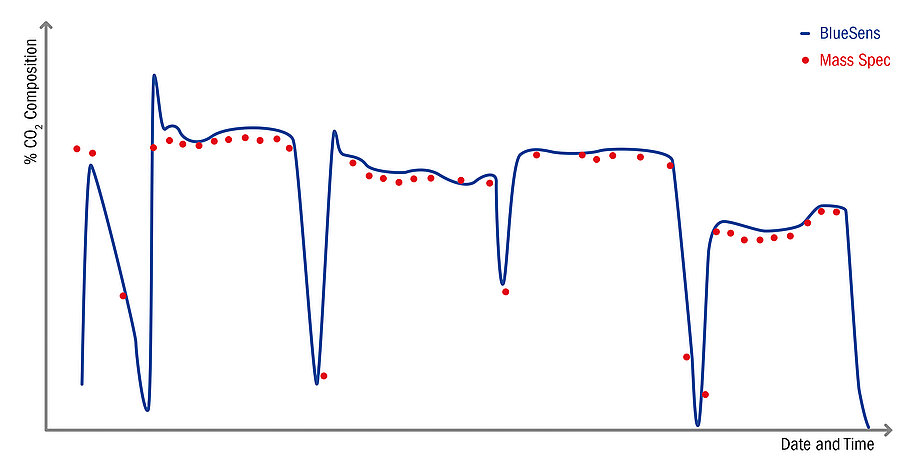

Although you already might have a mass spec in use additional BlueSens off gas analyzers can be beneficial. Especially with respect to PAT further off gas analysis equipment is a must. Why? Within development of robust and high yielding bioprocesses, monitoring and analysis of certain process parameters is essential. Following the PAT initiative for optimization of production processes, documentation of critical process parameters is needed. Besides analyzing off line samples applying work intense chromatographic and spectroscopic processes, some parameters can also be determined in real time. Online analysis enables increased understanding of the processes which leads to improvement of the whole bioprocess [2,3]. In industrial bioprocesses mainly concentrations of oxygen (O2) and carbon dioxide (CO2) are analyzed because they give direct feedback on the metabolism of the cultivated cells [4]. For monitoring the gases being used and produced with a mass spec a sampling unit, which is connected to the reactor, is needed. Samples have to be taken in determined time frames and are then analyzed at an external MS device. Complexity, investment and maintenance cost, as well as the expenditure, for measuring the gas phase with a MS device are very high.

To make the most out of the investment cost the devices are usually connected to numerous fermenters which means that there are time laps from up to 20 or 30 minutes between single measurement points. Especially in fast growing cultures the information gaps between single measurements can lead to avoidable problems. Increasing the knowledge about the bioprocess requires continuous data generation and logging. This article is intended to show that it doesn´t have to be either/or but that the two measuring technologies can complete each other. Users of an MS device can still substantially benefit from off gas analysis.

Continous off gas measurement using BlueSens gas analyzing technology

Applying both technologies in parallel data measured can be compared and processes are designed more fail safe. BlueSens gas analyzing technology reliably delivers continuous data in real-time. Analyzers are installed directly in the off-gas flow behind the sterile barrier and are every time accessible for checking and calibration, even in long processes. In general operation is easy and can be done by the lab personal without any workshops or trainings,such as calibration which means that maintenance cost are low.

Online off-gas analyzation from BlueSens offers:

Online gas analyzers are:

- Reasonable

- Compact

- Flexible

- Easy in handling and maintenance

By the way: to all of you who would like to be even more flexible and cost efficient BlueSens offers a maintenance free analyzer – BlueVary. Depending on what you´d like to measure you can change the gas measuring devices (and therefor the types of gases) just by a click. There is nothing simpler than BlueVary.

[2] M.M. Schuler, I.W. Marison, Real-time monitoring and control of microbial

bioprocesses with focus on the specific growth rate: current state and

perspectives, Appl. Microbiol. Biotechnol. 94 (2012) 1469–1482.

doi:10.1007/s00253-012-4095-z.

[3] C. Mandenius, R. Gustavsson, Mini-review : soft sensors as means for PAT in

the manufacture of bio-therapeutics, J Chem Technol Biotechnol. 90 (2014)

215–227. doi:10.1002/jctb.4477.

[4] F. Valero, J. López-Santín, Online Analysis for Industrial Bioprocesses : Gas

Analysis, Elsevier B.V., 2017. doi:10.1016/B978-0-444-63663-8.00022-7.