Measure O2/CO2 in parallel in just one device

The BlueInOne gas analyzer is space-saving and made of stainless steel. It can be easily operated via 2 buttons on the surface.

If you want more flexibility, then the BlueVary is a better alternative for you.

Using BlueInOne Ferm oxygen and carbon dioxide concentrations in your bioprocess can be monitored online and in real-time. Sitting in the exhaust gas flow behind the sterile barrier, the device can be calibrated at any time without causing potential contamination issues. Sampling systems, valves or pumps are unnecessary. Fluctuations of pressure and humidity are automatically compensated. Thus readings are both extremely accurate and precise. BlueInOne fits on every fermenter from benchtop to industrial scale.

BlueInOne Ferm – robust and precise gas analysis to help you understand your process

- Parallel measurement of O2 and CO2 ➔ no need for sampling

- different CO2 and O2 ranges available

- Compact stainless steel housing ➔ robust and easy to clean

- PAT and QbD conform in-situ-measurement ➔ for highest standard of quality

- Auto compensated humidity and pressure ➔ no need for extra gas coolers, pumps or valves ➔ highest fail safety

- Real time process optimization ➔ see what happens when it happens – fast response options

Application areas

- Bioprocesses in general

- Online fermentation monitoring

- From lab to industrial scale

Protect your sensor during steam sterilization

The SGP-1 sample gas pump from BlueSens is installed between the pipe and your analyzer. During the sterilization process, it cools down the gas, collects the water and thus protects your sensor from damage.

The analyzer can remain mounted during the entire process.

Sounds good?

Don't waste budget and "Use what you have"

Before you go and buy something new: check your lab! It might be enough to just buy several new components. We can show you how to turn your older equipment into a modern, fully equipped and controlled system.

Go and check your lab cabinets for

- an (older) culture vessel, bioreactor or fermenter

- pH, pO2 probes

- agitator control

- digital mass flow controller or flow meter

- pumps for feed addition and pH control

- open software BlueVis 4.0

- off-gas analyzers suitable for your application

Do you already have some of these items? — Perfect! With open bioprocess software BlueVIS we will connect all components and make your system run. Various communication protocols already have been integrated in BlueVIS. If yours is not supported yet, we will realize it.

Use what you have — Think sustainable and keep your invest low

- Don't waste money on installation fees or trainings

- Use equipment from manufacturers that you want to and not that you're told to

- BlueVIS 4.0 is compatible with other process-control software via OPC

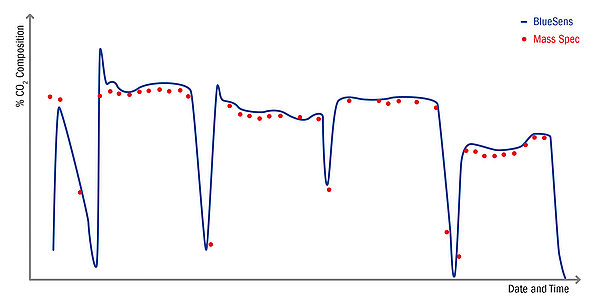

Benefit from continuous off-gas data

See what´s happening when it´s happening. MS and off-gas analyzers - it doesn't have to be either or but can also be complementary. Read here why and how to benefit from continuous off gas measurement made by BlueSens although you already might have a mass spec.

OEM sensors – customized sensors are our daily business

BlueSens' high quality measurement technique integrated in your device or provided with your label? We are already producing our sensors OEM for market leading fermenter manufacturers.

If you are interested in an individual OEM solution, please