Technical Short Facts

- Measuring principle Zirconium dioxide, Galvanic cell

- Measuring range 0,1-25 Vol.%, 1-50 Vol.%, 0-100 Vol.% (others on request)

- Drift < ± 2% value / year

- Accuracy <0,2% FS (full scale) ± 3% value

- Housing Aluminium (IP65), PA

- Mechanical connections G 1¼”, GL 45, Tri-Clamp SMS38, hose connection 4-12 mm etc.

- Temperature inside of the sensor unit 580°C 1076°F 3°C higher than process temperature 5.4°F higher than process temperature Don‘t use in explosive atmosphere

- Output RS232, 4-20mA, Ethernet (with BACCom), USB

Oxygen is the essential element of life and its measurement resembles a central point in controlling biotechnological processes. Applying BPC-O2 gas analyzers oxygen concentrations can be measured in situ directly from the exhaust gas flow. In combination with a bioprocess software (such as BlueVIS) the BCP-O2 can be used to calculate essential respiration parameters as OUR (oxygen uptake rate) and RQ (respiratory quotient). The BCP-O2 can be connected to the exhaust vent of any type or scale of fermenter and bioreactor, allowing you to scale up using the same measurement technology at every step. All BCP-analyzers are available with aluminum (pilot to industrial scale use) or PA (lab scale) casings.

BCP-O2 – non-invasive measurement independent from flow and scale

- in-situ gas analysis ➔ non-invasive measurement directly where it happens

- flow and scale independent ➔ one type of analyzer (technology) type for all scales ➔ less variations and unpredictable influences

- direct integration in gas pipelines behind the sterile barrier ➔ calibrate your analyzer at any time without the risk of contamination

- pressure and temperature compensated automatically leading to high accuracy and process reliability

- universal mounting opportunities for convenient integration on new or existing equipment

- standardized data interfaces for simple connection to any process lead system (PLS)

Application areas

- pharmaceutical industry

- biogas plants

- any type of fermentation processes

- laboratory scale

- large industrial plants

- (parallel) bioreactors

- connection to single-use reactors available

BCP-O2, zirconium dioxide, suitable for 0,1-25 Vol.% and 1-50Vol.%

BCP-O2ec, galvanic cell, suitable for 0-100 Vol.%

Protect your sensor during steam sterilization

The SGP-1 sample gas pump from BlueSens is installed between the pipe and your analyzer. During the sterilization process, it cools down the gas, collects the water and thus protects your sensor from damage.

The analyzer can remain mounted during the entire process.

Sounds good?

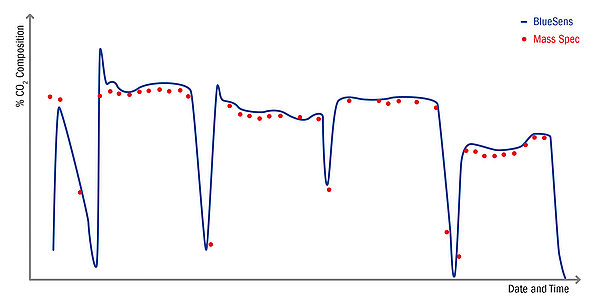

Benefit from continuous off-gas data

See what´s happening when it´s happening. MS and off-gas analyzers - it doesn't have to be either or but can also be complementary. Read here why and how to benefit from continuous off gas measurement made by BlueSens although you already might have a mass spec.