Technical Short Facts

- Auto-compensation of humidity, pressure, temperature to display lN

- No water or oil refill necessary

- Integrated display for data information at any time

- Superior quality components, extremely durable and robust

- BlueVIS ready via Modbus RTU for higher grade of automation

Looking to optimize your process?

BlueVCount is a versatile tool for measuring gas volumes in a wide range of reactions. The volume and accuracy of information it provides leads to optimized yields in fewer experiments and its integrated display offers easy access to results.

BlueVCount is a gas volume measurement device to measure gas flows online and in real-time in reactions of all kind. It is applicable in biological or non-biological reactions, academic or industrial, research labs or production sites.

BlueVCount can be used in fermentations, degradation or substrate comparison studies, wastewater treatment studies, bioethanol production and is especially helpful in measuring gas flows in biogas processes or residual gas analysis. Gas volume measurement delivers important information about the process and helps to optimize yields and process procedures.

Values measured by BlueVCount are automatically normalized meaning they are auto-compensated for humidity, pressure and temperature. No additional calculations necessary.

BlueVCount features a resolution of 1mL with a maximum flow rate of 80ml/min and does not need a minimum flow rate. With an accuracy of +/- 2% BlueVCount offers the most accurate measurements.

Product-Video

How does it work

BlueVCount is a volume measuring unit with a 1 ml cylinder that is equipped with an oil (special) sealed magnetic piston. It counts how often 1 ml gas comes through the cylinder and reports to the integrated display or to a software (e.g. BlueVIS) via Modbus RTU . Maximum flow rate is 80ml/min - no minimum flow rate.

Areas of application

- Every application in which gas is being produced

- Academics and industry

- Public and private laboratories

- Food and feed industry

- Biogas, bioethanol and residual gas analysis

- Wastewater treatment

- Suitable for biological as well as non-biological applications

What do you need?

| BlueVCount | Gas Endeavour* | Milligas- counter** | |

| Minimum flow | No need | ≥ 2(9)ml/min | 1ml/h |

| Maximum flow | 80ml/min | 24(110)ml/min | 20ml/min |

| Accuracy | ±2% | n.a. | ±3% |

| Resolution | 1ml | 2(9)ml | 3ml |

| Absorber possible | yes | yes | yes |

| Limit of data logging | unlimited | 2x104 | unlimited |

| Ethernet interface | no | yes | no |

| Modbus (RS485) | yes | no | no |

| Single device available | yes | no | yes |

| Gas tank/bag connectable | yes | yes | yes |

| Auto-compensation of humidity, pressure, temperature to display lN | yes | yes | no |

Options for CH4 measuring

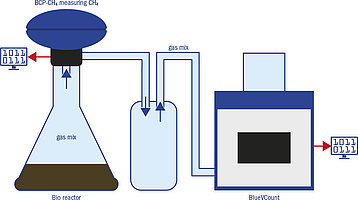

The BlueSens method

BCP-CH4 is connected to the bioreactor and measures CH4 concentrations in the gas mixture. Gas is led through a bottle and on the other side of the experimental setup BlueVCount measures the gas volume.

Advantage: CH4 concentration and gas volume at once, no chemicals needed, accurate AND precise

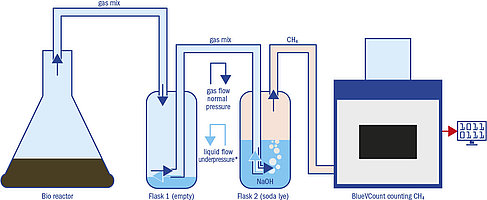

The BlueVCount method

Gas mixture is led through a first (empty) bottle which in case of over pressure in the system would store liquid from the 2. bottle. The second bottle is filled with soda lye to absorb CO2 from the gas mixture. BlueVCount at the end of the setup measures the gas volume

Advantage: CH4 100% absorption can be achieved, negative pressure is compensated

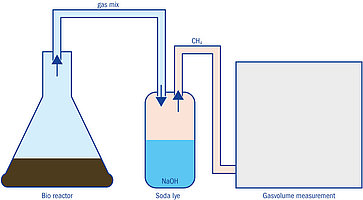

The traditional method

The traditional way of measuring CH4 in a gas mixture is to lead the gas out of the bioreactor into a bottle with soda lye. Soda lye is supposed to absorb the CO2 from the gas mixture so only CH4 is left. All other volatile components are not absorbed. Leftover gas is then led to a gas volume measurement device.

- Chemicals are needed to perform this method

- Negative pressure might occur.

- Absorption of CO2 in soda lye is 98%. When gas is led through the lye an absorption of 100% can be achieved until lye is saturated with CO2 (must be calculated carefully).

Technical Facts

| BlueVCount | |

| Minimal volume flow | 0 ml/h |

| Max. volume flow | 4.800 ml/h |

| Mechanical protection up to | 12.000 ml/h |

| Resolution (standard volume) | 1 ml |

| Deviation from value | ±2% |

| Gas pressure needed | >3hPa |

| Working voltage | 24V |

| Data format | Modbus RTU |

| Baud rate | 38400 |

| Physical interface | RS485 |