Connect what you want

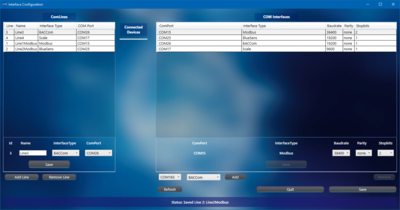

BlueVIS bioprocess software offers you the possibility to control and monitor several processes simultaneously. Many devices and sensors that are necessary to run a (PAT conform) fermentation process, such as pH and pO2 probes, pumps, stirrers, mass flow controllers already have digital outputs and can therefore be connected directly to BlueVIS. For analog signals, we use cost-effective analog/digital converters, so that you do not have to fill your laboratory bench with large control towers. Thanks to its open structure, BlueVIS allows you to connect hardware from any manufacturer. It´s your choice.

You are completely free to decide which devices you want to use, no matter whether you have purchased new equipment or are planning to use existing (maybe even older) equipment. True to the motto "Use what you have". Due to the integrated OPC server/client, BlueVIS is open to other software/systems. That means it can communicate with other systems and devices without any problems.

Important process data like CER, OUR, RQ, or µ are automatically calculated by BlueVIS. Furthermore, you can configure existing PID controllers yourself. In addition BlueVIS has a connection to MATLAB and other process control software. All data is stored in the database and visualized as freely configurable graphs. Of course, data can be exported as well.

Necessary hardware requirements

- Operating system Windows 10 64 bit or newer

- Modern processor with at least 4 cores and > 2.6 Ghz (e.g. Intel i5)

- Hard disk: SSD recommended with at least 50GB free space (> 500MB/s data access)

- 16GB RAM

- Display >= 24" 1920x1080px (FHD)

- usage of more than 4 fermentes might require more performant components

With BlueVIS - You are the boss

Why BlueVIS?

- Monitors and controls numerous processes in parallel

- No control towers needed (save bench space)

- Configure your own standard PID Controller

- Connections to MATLAB, BioCommand®, MFCSWin, Lucullus®, BioExpert, Dasware®, Eve® and more

- Can online calculate process data like CER, OUR, RQ, µ and biomass

- Special biogas edition available

- Takes data from different instruments of various manufacturers

- OPC Server/Client included as standard

Save your budget with BlueVIS

- Different licences for 1, 4, 8, 12 fermenter or biogas license available

- Fair pricings for updates to newer versions (e.g. Update BlueVIS 2 to BlueVIS 4)

- Updates within the version (e.g. BlueVIS 4) are free of charge

- YOU decide which equipment you like to use

- Save your money: reactivate your (older) equipment with no problems