Applications for BCP-H2

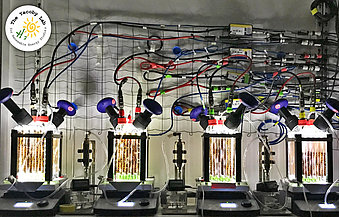

BCP-H2 is ideally suited for use in the field of hydrogen production using algae.

Due to the measuring principle, the sensor is only suitable for binary, non-flammable gas mixtures and provides stable results here.

Like all BlueSens sensors, the sensor must not be used as a warning device or in ATEX zones.

Technical Short Facts

- measuring principle: thermal conductivity detector (for binary nonflammable gas mixtures)

- concentration ranges: H2: 0 – 10 Vol.%, 0 – 50 Vol.%, 0 – 100 Vol.%

- accuracy: < 0.2% FS (full scale) ± 3% reading

- drift: < ± 2% reading / year

- temperature: different temperature ranges available

- pressure range: 0.8 - 1.3 bar/11.6 – 18.85 psi absolute pressure

- housing: aluminium (IP65) or PA

- cross sensitivity: BCP-H2 provides the best measurement results in binary gas mixtures and intert gases

The BCP-H2 is a cost-effective sensor that is particularly well suited for use in the field of hydrogen production by algae. The sensor uses the principle of thermal conductivity which means that it has cross sensitivities with other gases. The degree of cross sensitivities depends on the thermal conductivity of the other gases in the mixture. The sensor is therefore suitable for binary (non-flammable) gas mixtures, such as e.g. H2/CO2, H2/N2 and H2/Ar.

BCP-H2 can be connected to any size of cutur vessel. No matter if it is a shake flask or a (photo)bioreactor, it always fits thanks to the numerous mechanical connection possibilities.

All sensors of the BCP series are available with either aluminum or PA housing.

Don't waste budget and "Use what you have"

Before you go and buy something new: check your lab! It might be enough to just buy several new components. We can show you how to turn your older equipment into a modern, fully equipped and controlled system.

Go and check your lab cabinets for

- an (older) culture vessel, bioreactor or fermenter

- pH, pO2 probes

- agitator control

- digital mass flow controller or flow meter

- pumps for feed addition and pH control

- open software BlueVis 4.0

- off-gas analyzers suitable for your application

Do you already have some of these items? — Perfect! With open bioprocess software BlueVIS we will connect all components and make your system run. Various communication protocols already have been integrated in BlueVIS. If yours is not supported yet, we will realize it.

Use what you have — Think sustainable and keep your invest low

- Don't waste money on installation fees or trainings

- Use equipment from manufacturers that you want to and not that you're told to

- BlueVIS 4.0 is compatible with other process-control software via OPC

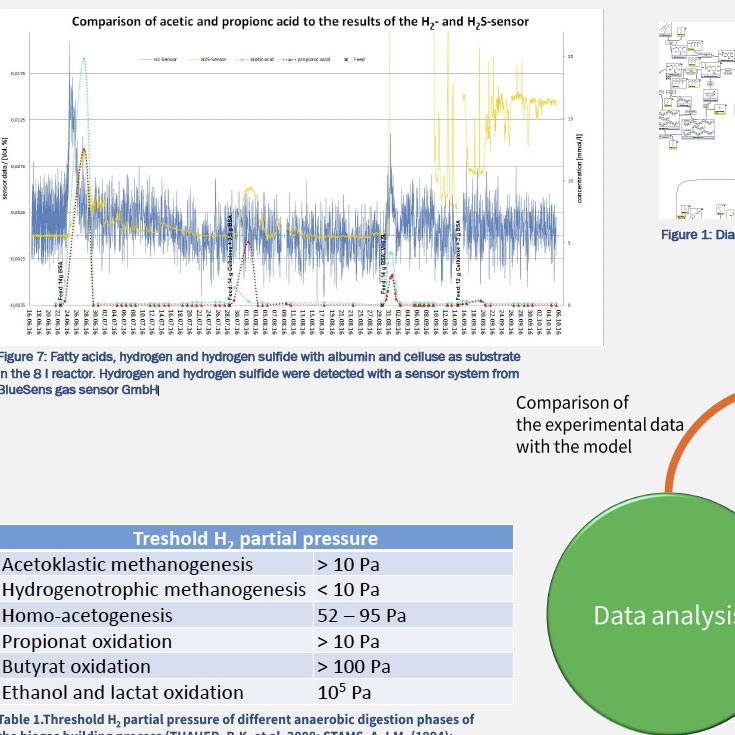

Benefit from continuous off-gas data

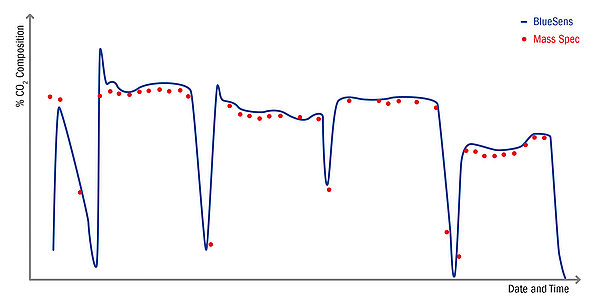

See what´s happening when it´s happening. MS and off-gas analyzers - it doesn't have to be either or but can also be complementary. Read here why and how to benefit from continuous off gas measurement made by BlueSens although you already might have a mass spec.

OEM sensors – customized sensors are our daily business

BlueSens' high quality measurement technique integrated in your device or provided with your label? We are already producing our sensors OEM for market leading fermenter manufacturers.

If you are interested in an individual OEM solution, please